When it comes to heavy-duty vehicles, towing performance, or off-road builds, the design of the axles plays a significant role in both durability and capability. If you’ve ever looked into upgrading your axle setup or had work done on your differential, you may have heard the terms "full-float" and "semi-float." These refer to how the axle handles load and torque—and the differences matter more than most drivers realize.

Understanding these two axle types helps you make informed decisions, whether you're customizing a truck, hauling serious weight, or simply curious about how your drivetrain works.

What Does “Float” Mean in Axle Terms

In basic terms, the word “float” describes how the axle shaft supports weight and handles motion. In a semi-float axle, the shaft itself bears the weight of the vehicle and transmits power from the differential to the wheels. In a full-float axle, the shaft’s only job is to transfer torque, while the axle housing and wheel hub support the weight.

This difference may seem small, but it significantly affects a vehicle's strength, maintenance, and its behavior under load.

Semi-Float Axles: Common in Most Light Trucks and SUVs

Semi-float axles are the most widely used design in light-duty vehicles. You’ll find them in many pickup trucks, vans, and SUVs. In this setup, one end of the axle shaft is splined into the differential, and the other end is bolted directly to the wheel hub or flange. This means the axle shaft is doing double duty: holding up part of the vehicle’s weight and spinning the wheels.

Because of this dual function, semi-float axles tend to be less robust than their full-float counterparts. They’re generally easier and less expensive to manufacture, which is why they’re so common. But when it comes to towing, hauling heavy loads, or enduring off-road abuse, they reach their limits much sooner.

Full-Float Axles: Built for Heavy-Duty Use

Full-float axles are designed for strength and longevity. In this design, the wheel hub rides on its own bearings on a spindle that extends from the axle housing. The axle shaft is splined into the hub but doesn’t carry the vehicle's weight. Instead, all the load is supported by the housing and the bearings.

This setup provides several key benefits:

- Greater load-carrying capacity

- Less stress on the axle shaft

- Easier shaft replacement without removing the wheel or hub

- Better durability under harsh conditions

You’ll usually find full-float axles in heavy-duty trucks, commercial vehicles, and high-performance off-road builds. They’re especially useful when towing trailers, hauling construction materials, or tackling extreme terrain.

How to Tell Which Axle You Have

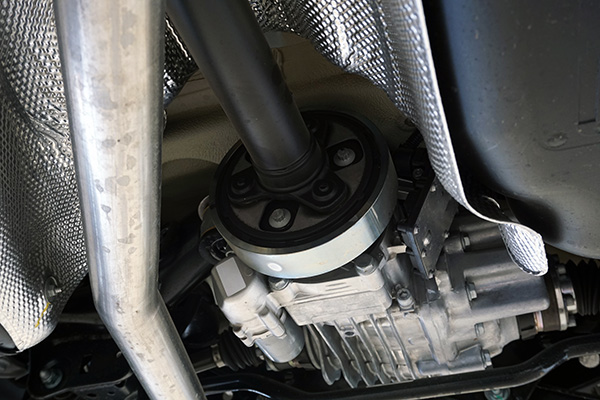

The easiest way to identify a full-float axle is to look at the hub. Full-float axles often have a large protruding hub with multiple bolts surrounding it, indicating that the axle shaft can be removed separately. Semi-float axles typically have a flush or recessed hub with fewer visible bolts, since the shaft is directly connected to the wheel.

Another way to tell is by checking the vehicle’s specifications or service manual. If your truck is rated for heavy towing or is labeled as a ¾-ton or 1-ton vehicle, there’s a good chance it has a full-float axle in the rear.

Which One Do You Need

If you use your vehicle for daily driving, light hauling, or moderate towing, a semi-float axle is usually more than enough. It keeps the vehicle lighter and more fuel efficient, and it’s easier to service when needed.

However, if your work or hobbies involve heavy loads, large trailers, or rugged trails, the full-float axle is the safer and more reliable choice. It can handle more torque without bending or breaking, and it holds up better over time under severe conditions.

Some drivers choose to upgrade to a full-float system even if they don’t strictly need it, just for peace of mind or added resale value. It’s an investment in long-term performance.

Can You Convert from Semi-Float to Full-Float

Yes, but it’s not a minor job. Converting to a full-float axle involves replacing the axle housing, hubs, and possibly the differential. The process requires specialized knowledge and tools, which is why experienced drivetrain shops typically do it.

For certain vehicles, full-float axle kits are available, but compatibility and installation complexity vary. Before attempting a conversion, it’s important to weigh the costs and benefits based on how you actually use your vehicle.

Get Expert Drivetrain Advice in Riverside, CA

At Premier West Gears in Riverside, CA, we work on everything from light-duty daily drivers to extreme off-road rigs and heavy haulers. If you’re considering an axle upgrade or want to know whether your setup can handle more stress, our technicians can inspect your system and help you choose the right solution.

Whether you're maintaining, upgrading, or rebuilding, we’re here to keep your drivetrain performing at its best.